Exercitation ullamco laboris nis aliquip sed conseqrure dolorn repreh deris ptate velit ecepteur duis.

Höfert Italia's Products

_________________

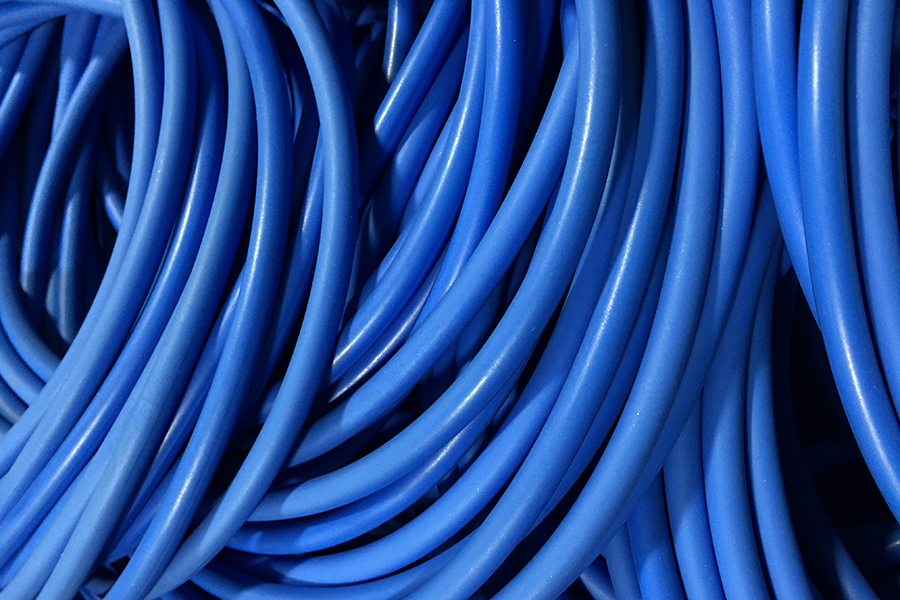

Höfert Italia has specialised in the production of O-ring seals and technical items.

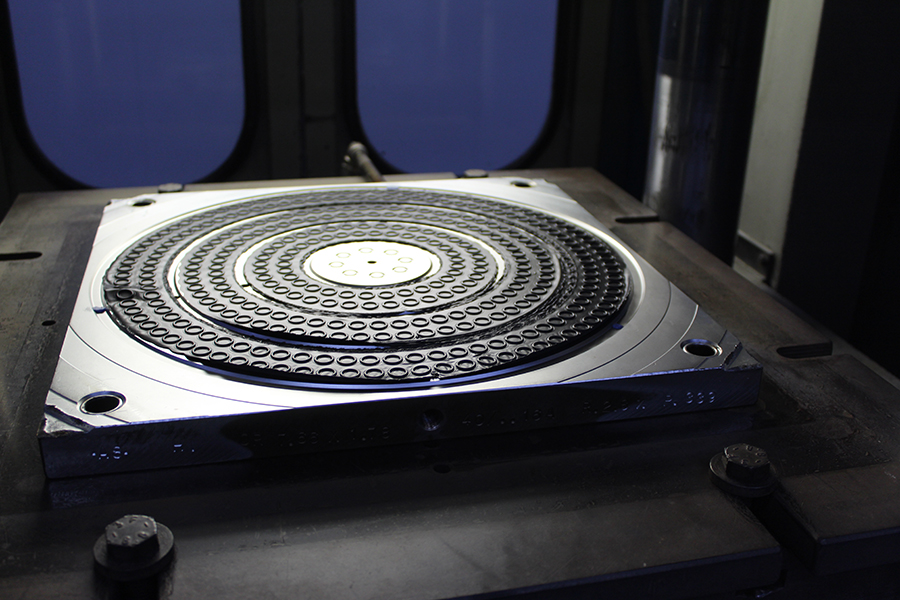

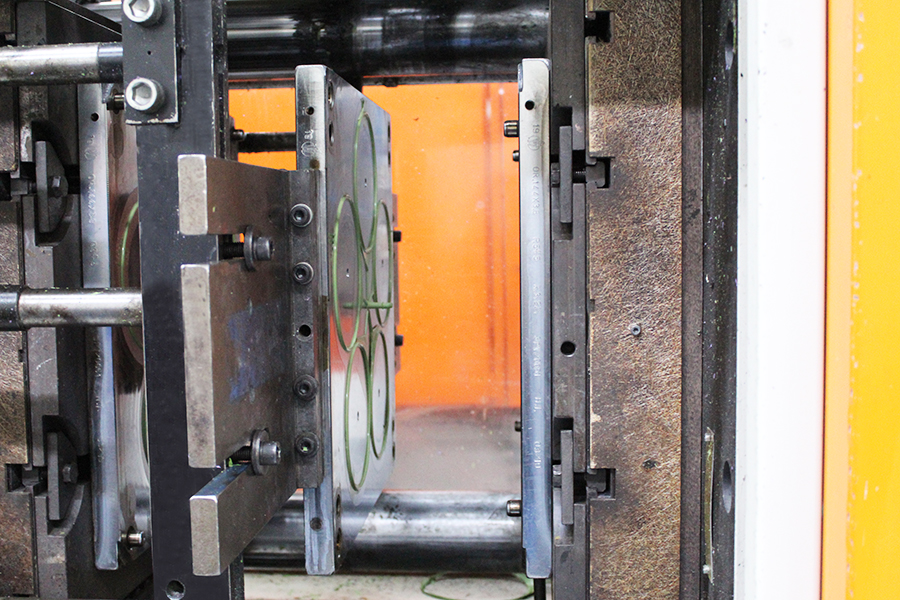

The standard dimensional tolerances for the O-rings are given in the standard ISO 3601-1. As concerns the technical items, the tolerances generally applied are ISO 3302-1 (ex DIN 7715 M2) or those required upon Customer’s drawing. The different production stages are constantly monitored according to an accurate control plan based on real-time technology. From the acceptance of raw materials to the final packaging of the items, our production cycle – methodically controlled by making use of high precision equipment – allows us to obtain a product with an excellent quality/price ratio.

Our production department has approximately 6,000 moulds available to obtain as many dimensions of O-rings (3,400 injection moulds – 600 compression moulds) and approximately 500 moulds for shaped items upon Customer’s drawing. The O-ring sizes range from 0.50 to 1025.00 mm of internal diameter and from 0.50 to 20.00 mm of cord thickness. Download the format Excel file to get our updated range of moulds.

Fields of application

Automotive

Oil production

Hydraulics

Lighting

Pneumatics

Food production

Fields of application

Automotive

Oil production

Hydraulics

Lighting

Pneumatics

Food production

Families of compounds

_________________

FKM

Fluorinated

FFKM

Perfluoro-

elastomer

NBR

Nitrile or Oil-proof

EPDM

Standard and Peroxy

EAM

Ethylene-acrylate

HNBR

Oxygenated nitrile

VMQ

Silicone

FVMQ

Fluor-silicone

PVMQ

Fenil-silicone

CR

Neoprene

ACM

Polyacrylic

SBR

Butadiene Styrene

AFLAS

–

Polyurethane

–

Families of compounds

_________________

FKM

Fluorinated

FFKM

Perfluoroelastomer

NBR

Nitrile or Oil-proof

EPDM

Standard and Peroxy

EAM

Ethylene-acrylate

HNBR

Oxygenated nitrile

VMQ

Silicone

FVMQ

Fluorsilicone

PVMQ

Fenilsilicone

CR

Neoprene

ACM

Polyacrylic

SBR

Butadiene Styrene

AFLAS

–

Polyurethane

–